Fully tempered glass and spontaneous fracture

Risk due to NiS-induced spontaneous fracture

Safety risks to building occupants and the public

The risks of injury due to falling glass fragments can vary depending upon the height of the glass and location relative to people. Clearly, there is a different level of risk of injury or property damage associated with glass fallout from several stories above a busy sidewalk compared to fallout from an interior glass partition directly adjacent to building occupants. Note, the International Building Code (IBC) recognizes reduced risk of falling fragments of fully tempered monolithic glass within 3 m (10 ft) of a walking surface for sloped and overhead glazing (IBC 2015 Section 2405.3.1). Ultimately designers need to exercise careful judgement in glass selection to minimize project-specific risk.

Extents of contamination and duration of breakage events

Float glass is manufactured in large batches, often with float stock produced at a single facility. Although the percentage of buildings experiencing spontaneous breakage of fully tempered glass due to NiS inclusions is low, if a batch of glass is contaminated, the incidence of breakage on a particular building can be quite high. The probability of NiS-induced fracture in each population of fully tempered glass is unpredictable because of many variables such as:

- the likelihood and quantity of contaminates in the furnace

- the potential location of inclusion within the tension zone of the glass

- the probability of the NiS occurring in the less-stable alpha phase

Once fracture occurs, the possibility of the glass fragments remaining in place (i.e. retained in the frame) is also unpredictable and dependent on a variety of factors including, but not limited to:

- size and thickness of glass

- exposure to post-fracture lateral forces such as from air movement (e.g. wind)

- magnitude of energy release during fracture (a function of magnitude of residual stress built into the glass)

- location of NiS inclusion within the glass

- presence of laminating interlayers

- adhesion/stiffness of glass retention by the perimeter frame

Therefore, unless the fractured lite is laminated to an unbroken lite, there is no definitive set of circumstances under which one can feel confident the fragments will be retained in place after fracture. Additionally, although a laminated sheet of glass retains the fractured lite, the laminated lite will no longer have the same stiffness or resistance to in-service loads.

Industry practice to mitigate risk

It has been recognized in the architectural glass industry for decades that fully tempered glass can fracture spontaneously due to the presence of NiS impurities. For this reason, major glass manufacturers have advised that fully tempered glass should be avoided in applications where a fracture and glass fall-out pose a substantial risk of harm to people or property. A major glass manufacturer addressed this issue in a technical bulletin, first published in 1988. In this document, the manufacturer confirmed this inherent susceptibility of fully tempered glass to spontaneous breakage in-service, and refused to knowingly supply monolithic, fully tempered glass for “street wall” applications.

Limiting the use of fully tempered glass

Industry practice is to limit the use of fully tempered glass to only locations required by code. The National Glass Association (NGA’s) GANA Glazing Manual is the industry standard for the design, fabrication, and installation of glass and warns of the risk of NiS-induced spontaneous breakage of fully tempered glass and advises:

“The potential risk of spontaneous breakage associated with nickel sulfide inclusions can be minimized by using heat-strengthened glass due to the lower stresses in heat-strengthened glass. Where fully tempered glass is not required by building codes (safety glazing, fire breakouts, etc.) and/or design loads, heat-strengthened glass is normally the preferred product.”

In some cases, fully tempered glass is mandated by the building code (e.g. safety glazing and in some jurisdictions, fireman knock-out panels) or required for strength (e.g. to resist high thermal stress or tension due to design loads), as is often the case for point-supported and other similar “structural” glass applications as a result of high tensile stresses around the anchors and glass fittings.

Despite these requirements, building codes are adapting to further limit prescriptive use of fully tempered glass. For example, Exception 3 in IBC 2024 Section 2406.4.3 (Figure 5) exempts the exterior lite of multi-lite glass units with bottom exposed edge 2.44 m (8 ft) or more above the adjacent walking surface from safety glazing requirements, substantially reducing the application of fully tempered glazing on building facades compared to prior editions. The 2.44 m (8 ft) dimension is an important revision from the long-standing 7.6 m (25 ft) dimension in previous editions of IBC.

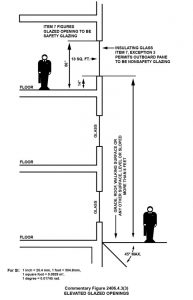

Designers can also employ Exception 2 in 2024 IBC Sec. 2406.4.3 to provide a horizontal rail inboard of a hazardous location (e.g. a floor-to-ceiling vision glass application) to eliminate the need for safety glazing (Figure 6). A horizontal rail can often be incorporated directly into the glazing system with minimal visual implications.

Photo courtesy Simpson Gumpertz & Heger (SGH)

Laminated glass is another alternative to monolithic fully tempered glass to meet safety glazing requirements. Laminated glass can also enhance the post-breakage performance compared to monolithic glass. Building codes reflect this practice, for instance the 2015 IBC and later editions explicitly requires the use of laminated glass in structural glass handrails and guards unless “there is no walking surface beneath them or the walking surface is permanently protected from the risk of falling glass.” Note, laminated glass often comes at a cost premium compared to monolithic fully tempered glass and therefore its cost-benefit should be evaluated on a case-by-case basis.

Beyond evaluating the need for safety glazing, it is important to not accept use of monolithic fully tempered glass without also reviewing structural and thermal stress calculations, confirming it is, in fact, required, as one may be taking on unnecessary risk in employing fully tempered glass when heat-strengthened glass would suffice. Additionally, fully tempered glass is sometimes produced in lieu of heat-strengthened for convenience and/or for economic reasons, and not because of code or strength requirements. In any case, design professionals should not accept monolithic fully tempered glass unless its requirement for the project is proven.

In these cases, where monolithic, fully tempered glass is unavoidable, major glass manufacturers have advised and industry practice suggests glass should be heat-soak tested as a means to reduce the risk of in-service breakage due to NiS inclusions.

| DISPELLING MYTHS ABOUT SPONTANEOUS FRACTURE |

| The terms discussed regarding fully tempered glass, spontaneous fracture, and heat-soak testing can be confusing. This has led to misinformation, false claims, and myths as discussed and clarified below.

Myth #1: If glass on a project has a statistical probability of breakage (SPB) of 8/1000, one should expect to have eight broken lites of glass for every 1000 pieces of glass on the building during construction or in-service. Myth #2: Heat-soak testing reduces SPB from 8/1000 to 5/1000. Myth #3: Heat-soak testing eliminates all risks of spontaneous breakage of fully tempered glass in-service. Myth #4: Foreign-sourced float glass is at higher risk of NiS contamination compared to domestically-sourced glass. Myth #5: NiS-induced spontaneous fracture of fully tempered glass runs its course in the first three to seven years, after which breaks will eventually stop. |