Tile and Stone Lippage: What is acceptable (and how do you specify it?)

Conclusion

Excessive lippage can lead to damaged tile edges as various objects traveling over the floor hit these unsupported tile edges. It can also cause trip-and-fall incidents, particularly for those who shuffle when they walk and/or use walkers. Even in commercial settings, tile lippage can be problematic and annoying as carts and other equipment clack as they run over tile edges.

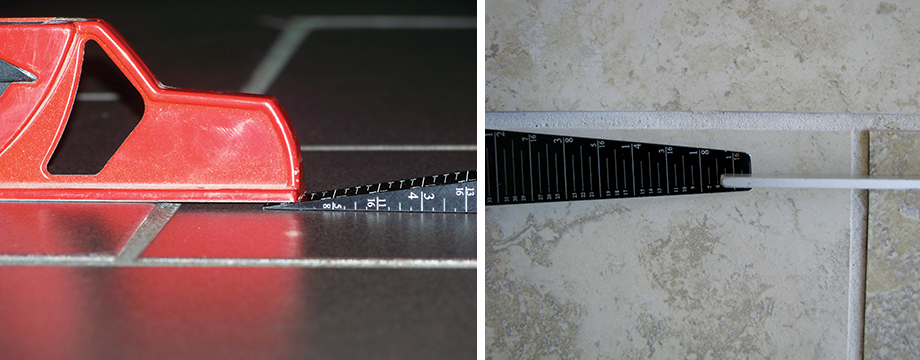

Excessive tile lippage can be avoided with quality architectural specifications that include adequate QA testing, mockups, and QC processes. Excessive tile lippage is typically due to a combination of substrates not properly prepared, improper installation methods, improper use of materials, and poor installer workmanship. Perceived excessive tile lippage is typically due to improper lighting design, too narrow grout joints, and not following industry recommendations. In some cases where perceived excessive tile lippage is unavoidable, it may be due to false expectations by the specifier or client. Having the tile installer using a Tile Leveling System can help minimize tile lippage.

To avoid these problems, architects must write thorough detailed specifications that are specific, complete, and clear. Installers must be current with industry standards and follow those standards and the manufacturers’ directions while installing the tile. Installers are mechanics with the skill level to provide quality workmanship, but they should not be expected to make architectural decisions—architects must give the installers the information and details they need to do their job correctly. Tile installation company management must provide adequate training and oversight of their employees to make sure they are performing the work per the specifications and the respective industry standards.

Most installers learn their skill on the job and do not have the opportunity to learn the industry standards. So it should be specified and verified that tile-installers are up to date with the current industry standards.

This author has never investigated a tile or stone failure and found all the industry standards and manufacturers’ instructions were followed. The problem is never due to one deficiency, but is always because of many compounding problems. Simply put, the key to a successful tile and stone installation is to follow industry standards and to write good specifications. MasterFormat and SectionFormat provide the structure for good-quality specifications, which, if used correctly and thoroughly, will limit both the designer’s (and the client’s) risk and liability when ceramic tile, glass tile, and stone applications are specified.

Donato Pompo, CTC, CSI, CDT, MBA, is the founder of Ceramic Tile and Stone Consultants (CTaSC) and the University of Ceramic Tile and Stone (UofCTS). He has more than 40 years of experience in the ceramic tile and stone industry from installation to distribution to manufacturing of installation products. Pompo provides consulting services in forensic investigations, quality control (QC) services for products and installation methods, training programs, testing, and onsite quality control inspection services. He received the 2012 The Construction Specifier Magazine Article of the Year Award. Pompo can be reached at donato@ctasc.com.