Clay brick passes recent fire resistance test

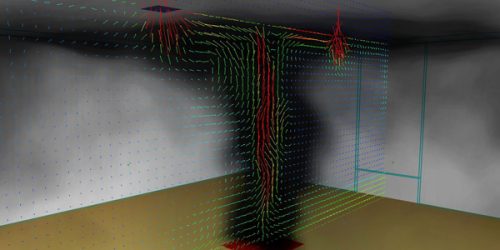

A one-hour fire test was conducted independently at the Southwest Research Institute in San Antonio, Texas. Hollow brick was tested alongside vinyl siding and fiber cement in typical residential exterior wall sections.