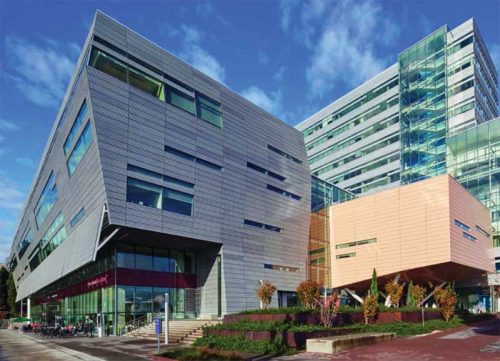

Failures: Persistent water leakage above ribbon windows

When through-wall flashing is not properly detailed or installed in cavity wall construction, the water penetration resistance of the enclosure can be compromised. This was recently observed at a multi-story office building in the southeastern U.S., that regularly experienced water leakage during prolonged rain events above ribbon window assemblies.