Designing barrier-free bathrooms

Water vapor permeance

According to ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials, water vapor permeance is:

the time rate of water vapor transmission through unit area of flat material or construction induced by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions.

Water vapor permeance can be used to characterize the effectiveness of a bonded waterproofing membrane in managing vapor in tiled showers. ANSI A118.10 was developed to evaluate membranes as barriers for liquid water migration and therefore does not include a minimum criterion for water vapor permeance. However, vapor management is essential in tiled showers and steam rooms given the elevated temperatures and relative humidity in these applications.

There is no universal requirement for vapor permeance of membranes in the building industry. The environmental conditions (i.e. differences in temperature and relative humidity [RH]), building materials, duration of exposure, and relevant field experience determine the appropriate membrane performance for a given application.

Recent developments in the tile industry indicate a maximum water vapor permeance requirement will be implemented in the Tile Council of North America’s 2013 TCNA Handbook for Ceramic, Glass, and Stone Tile Installation for continuous-use steam rooms (e.g. those found in health clubs and spas). Bonded waterproofing membranes for these applications must have a water vapor permeance of 0.5 perms or less when tested according to ASTM E96 using the desiccant method at 38 C (100 F) and 90 percent RH.

Under this scenario, the bonded waterproofing membrane is considered a vapor retarder that can effectively limit vapor transmission within the application and may be bonded to an integrated bonding flange drain. Higher water vapor permeance values may be allowed when a vapor retarder is implemented behind the solid backing on walls and lapped into a pan liner under the mortar base—similar to the traditional tile shower design previously described. In this case, the bonded waterproofing membrane prevents liquid water from infiltrating the mortar bed from the surface. The membrane must be attached to a clamping ring drain in such a way the weep holes remain open and the mortar bed can effectively drain.

Bonded waterproofing technology

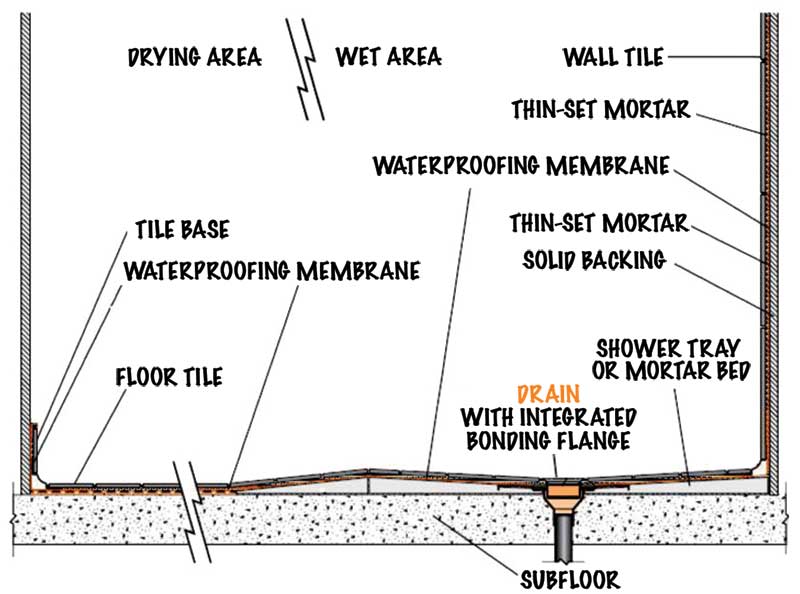

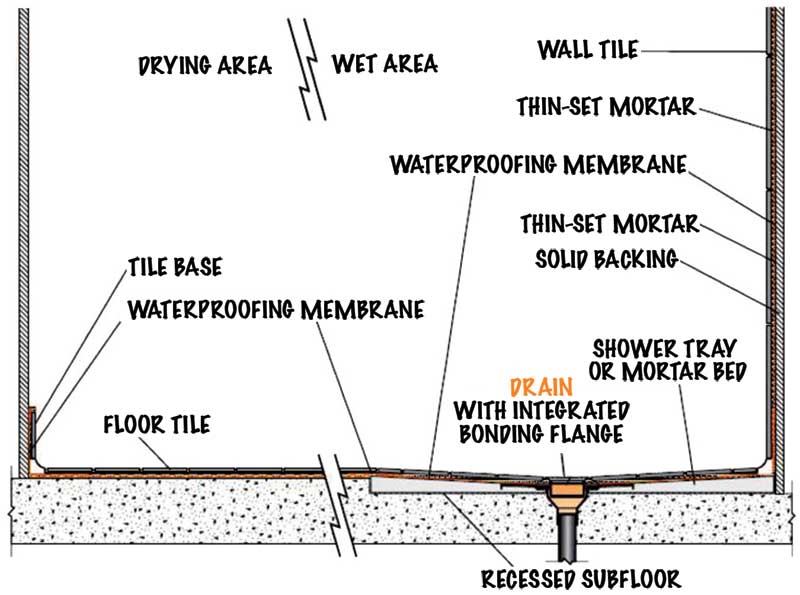

Barrier-free showers do not include curbs, and surface water typically may not be completely contained in the enclosure during use or as the individual leaves the shower. For illustrative purposes, the shower enclosure itself can be considered the ‘wet area’ and the rest of the bathroom the ‘drying area.’

The waterproofing membrane must be applied within the wet area over the shower base and up the walls to at least the height of the showerhead. There is no single requirement to guide the specifier in determining where the waterproofing membrane must be applied in the drying area. The conservative, and best, approach is to continue application of the waterproofing membrane across the entire bathroom floor and up the walls to the top of the tile base or wainscoting. This practice provides the highest level of protection without affecting the overall thickness of the tile assembly on the floors or walls.

Bonded waterproofing systems provide a simple and effective means of waterproofing barrier-free installations. The key to this is bonded waterproofing membranes are topically applied. Once the slope to drain is established, the membrane and tile are installed—this minimizes the assembly thickness.

Given the wide range of potential barrier-free configurations, it is impossible to address them all in this article. However, the following guidelines will assist in planning any barrier-free installation. Ideally, the floor will be recessed before installing a sloped mortar bed or prefabricated shower base to allow an even transition at the door threshold. This process can be relatively straightforward in new construction and can also be accomplished in renovations. When recessing the floor is not an option, a ramp up into the shower area must be provided.

Recessing the bathroom floor must be done in a way to preserve the structural integrity and safety of the construction, which may require the services of a qualified design professional (e.g. architect or engineer). Various building codes and other sources, such as the 2010 Americans with Disabilities Act (ADA) Standards for Accessible Design, include the specific requirements for disabled access in public buildings and must be consulted when applicable. Design considerations include degree of slope, clearance, and supporting structures, such as grab bars.