New IBC rules for insulation in unvented enclosed roof framing assemblies

The corresponding code commentary reproduced below provides vital clarification of this statement.

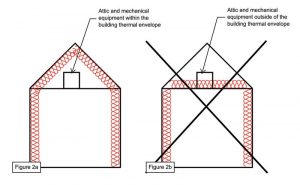

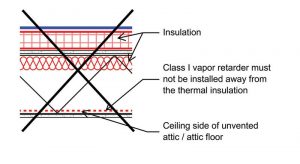

Commentary: Item 2, which applies to all climate zones, prohibits the installation of a vapor retarder where it is typically installed at the ceiling level (attic floor) of a traditional ventilated attic. This assures that no barrier is installed which would separate the conditioned attic area from the remaining portion of the home. This requirement gives the attic space a limited potential to dry into the space beneath the attic so that small amounts of excess moisture can be removed from the attic.

Authors’ interpretation: Vapor retarders limit vapor diffusion and, when properly placed, can prevent the formation of condensation on interior surfaces. Examples of Class I vapor retarders include polyethylene film or foil-faced insulation. When improperly placed within a roofing assembly or combined with another strong vapor retarder, such as a roof covering, they may lead to condensation or trapped moisture. Barring use of a Class I vapor retarder on the attic floor of the roof assembly seeks to limit the potential for trapped moisture from accumulating in the attic space (Figure 3).

- Where wood shingles or shakes are employed, a minimum 1/4-in. (6.4-mm) vented airspace separates the shingles or shakes and the roofing underlayment above the structural sheathing.

Authors’ interpretation: Providing a ventilation layer, specifically below wood shingles or shakes, allows back-drying of the wood shingles or shakes between rain events to limit moisture accumulation in the roof assembly and wood decay.

- In Climate Zones 5, 6, 7, and 8, any air-impermeable insulation shall be a Class II vapor retarder or shall have a Class II vapor retarder coating or covering in direct contact with the underside of the insulation.

Authors’ interpretation: Inclusion of a Class II vapor retarder on the winter-warm side of the assembly produces favorable hygrothermal performance and lowers risk of condensation in cold climates.

Examples of air-impermeable insulation include expanding sprayfoam (open- and closed-cell) and insulated sheathing panels. Open- and closed-cell sprayfoams may be air impermeable when installed in thicknesses greater than manufacturers’ minimum requirements. Closed-cell sprayfoam may form a Class II vapor retarder at certain minimum thicknesses, while open-cell sprayfoams are generally vapor permeable.

Air-permeable insulations include fiberglass batts, semi-rigid mineral wool boards, and most cellulose insulation products.

- Insulation shall be located in accordance with the following:

5.1 Item 5.1.1, 5.1.2, 5.1.3 or 5.1.4 shall be met, depending on the air permeability of the insulation directly under the structural roof sheathing.

Authors’ interpretation: If insulating below the roof sheathing deck, designers must select an approved insulation method described in the subsections.

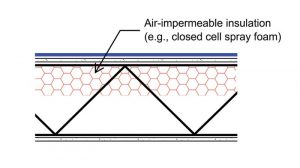

5.1.1. Where only air-impermeable insulation is provided, it shall be applied in direct contact with the underside of the structural roof sheathing.

Authors’ interpretation: Insulation that does not allow air movement through it (e.g. closed-cell sprayfoam) must be located on the underside of the roof deck (Figure 4).

5.1.2. Where air-permeable insulation is provided inside the building thermal envelope, it shall be installed in accordance with Item 5.1. In addition to the air-permeable insulation installed directly below the structural sheathing, rigid board or sheet insulation shall be installed directly above the structural roof sheathing in accordance with the R-values in Table 1203.3 for condensation control.