The versatility of stone wool for retrofits

Retrofits are complex undertakings, and each project is unique. Every building comes with its own history, conditions, and performance challenges. As a result, retrofits require a holistic approach that considers not only the project’s goals, but how all building systems will work together over the long term.

According to AIA Firm Survey Reports,1 work on existing buildings—whether that be renovations, rehabilitations, additions, or historic preservation—accounts for nearly half of the design activity at U.S. architecture firms. This trend is only expected to increase as building owners and operators look to do more with the buildings already in their portfolio.

Regardless of whether they are undertaking an exterior or interior retrofit, materials such as stone wool insulation can help teams meet and exceed modern energy efficiency and fire performance standards, while also offering durability for decades.

Why retrofit?

The motivation for retrofitting a building can be as varied as the buildings where these retrofits are undertaken. In some cases, the building is no longer performing as intended. It may be leaking rainwater, leading to mold growth and damp conditions. The indoor conditions may no longer be comfortable, with occupants complaining the interior is either too hot or too cold, indoor air quality has deteriorated, or their units do not have adequate acoustic insulation to keep them from overhearing neighbours or the outside world. And in other cases, retrofits are being driven by modern energy code requirements.

Retrofits are also increasingly common as buildings and neighbourhoods experience changes in use. Unoccupied buildings may need to serve a new function, with industrial buildings being repurposed for commercial purposes, or old office and commercial buildings being transformed into residential properties. Each of these can require significant changes to both the building interior and envelope to make the facility suitable for its new life.

However, even when buildings continue to operate as intended or their use remains unchanged, retrofits may still be necessary to address environmental concerns. Energy efficiency may need to be improved to achieve sustainability targets or reduce operating costs associated with energy consumption.

Globally, buildings account for nearly 40 percent of annual greenhouse gas emissions, and in large urban areas, this number is even higher.1 In New York City, for example, buildings account for 68 percent of the city’s CO2 emissions. Faced with the climate crisis, energy consumption continues to rise and is projected to increase by 50 percent by 2050 unless immediate action is taken.

Real estate in the U.S. is aging. More than 20 percent of non-residential buildings in the U.S. were built before 1960. The US Energy Information Administration has identified that 35 percent of buildings in the U.S. are between 45 and 80 years old, making them due for retrofit either to improve energy efficiency or to convert them for future uses.

For building systems to meet their operational, financial, and sustainability goals, multidisciplinary teams should view retrofits as a holistic solution, rather than a series of discrete tasks.

A systems approach is needed

Successful retrofits do not happen in isolation. Upgrading a single element without considering its impact on others can introduce new challenges, including condensation, reduced enclosure durability, and thermal bridging. This may lead to further unplanned and preventable repair costs in the future.

Approaching retrofits as a systemic undertaking that integrates the building envelope, fireproofing, mechanical systems, and long-lasting interior spaces creates a cohesive plan that saves money and resources in the long run.

But retrofitting is never a one-size-fits-all project. Along with the variety of existing issues a building may face, designers, specifiers, and contractors must consider the local climate and building codes. An office building in Canada will have significantly different space heating, cooling, and lighting needs than one in California.

However, the goal should always be durability, regardless of whether the work is a targeted upgrade or a total transformation and repurposing. A resilient retrofit—one with an intentional plan and use of high-quality materials that considers local climate conditions, building use, and code requirements—will result in a valuable property for decades to come.

Many types of retrofits

The first step in planning a retrofit is to understand the scale. Some projects may require only the work of onsite maintenance staff and a few contractors, while others will become multi-phase undertakings that require a multidisciplinary team. Whether preparing for a minor, major, or deep retrofit, the first step is to clearly define desired outcomes, which will directly inform the scope and scale of the project.

Minor retrofits

In many cases, a minor retrofit may be all a building needs to achieve long-term goals. Or it might provide a temporary solution until funds are available for a more complex project. Minor retrofits include improving energy performance and air quality through caulking or replacing seals and gaskets. These projects could also include increasing energy efficiency by upgrading lighting systems. Most of these minor activities could be completed within days or weeks, depending on the size of the building.

Major retrofits

When caulking and new lighting are not enough, a major retrofit may be required. These require the team to take a holistic view and will

involve higher costs with some (though often minimal) occupant disruption. A major retrofit might involve:

- Adding insulation and air sealing

- Replacing window glazing and doors

- Updating inefficient heating and cooling system components

- Installing low-flow faucets and plumbing fixtures, often with integrated sensors or automatic shut-offs

- Installing better building controls

Major retrofits can have a significant and often immediate impact, leading to better energy efficiency and building performance, as well as increased occupant satisfaction with the space where many people will spend a significant portion of their day.

Deep retrofits

When a building is changing its intended use or requires substantial upgrades to comply with modern building codes and sustainability programs, a deep retrofit may be needed. This involves significantly reconfiguring the interior while enhancing the larger building enclosure.

Deep retrofits can involve moving or removing walls, roof replacements, adding, moving or rearranging windows for increased daylight. They can also include replacing and upgrading HVAC systems to include more sustainable options such as heat pumps.

While more extensive, costly, and disruptive than minor or major retrofits, deep retrofits can also result in more savings, advanced building performance, and an ability for building owners to attract premium tenants or access better financing in the future.

Choosing the right strategy

Since the scope of retrofits can vary drastically, each project starts with understanding the building’s constraints, goals, and opportunities.

Interior

Buildings where exterior work is restricted by historic preservation rules and ordinances, zoning or lot line restrictions, and aesthetic requirements may be limited in how much work can be done from the exterior. When an interior retrofit is the best (or only) option, these projects need to be carefully scoped out to ensure airtightness is maintained, thermal bridging and transitions is managed, and disruption for building occupants is limited.

Exterior

Where owners and operators have more flexibility in altering a building’s exterior, or where energy goals and building repairs can’t be managed entirely through an interior retrofit, consultants and designers may recommend an exterior retrofit instead. While more complex, exterior retrofits can improve overall building durability and keep structural elements better protected by reducing condensation risks.

Exterior retrofits can present an opportunity to update the building facade, but may also require additional structural considerations related to increased insulation and cladding weight. A more extensive exterior retrofit can also direct designers and specifiers to consider improved fire protection to meet new building code requirements.

Why stone wool?

Regardless of whether the retrofit is for the interior or exterior, choosing the right materials plays a crucial role in enhancing building performance. Particularly in cooler climates, reduced drying potential can increase condensation risks. Selecting properly integrated air and water control layers is critical for preventing issues such as convection loops, trapped moisture, and surface drainage failures.

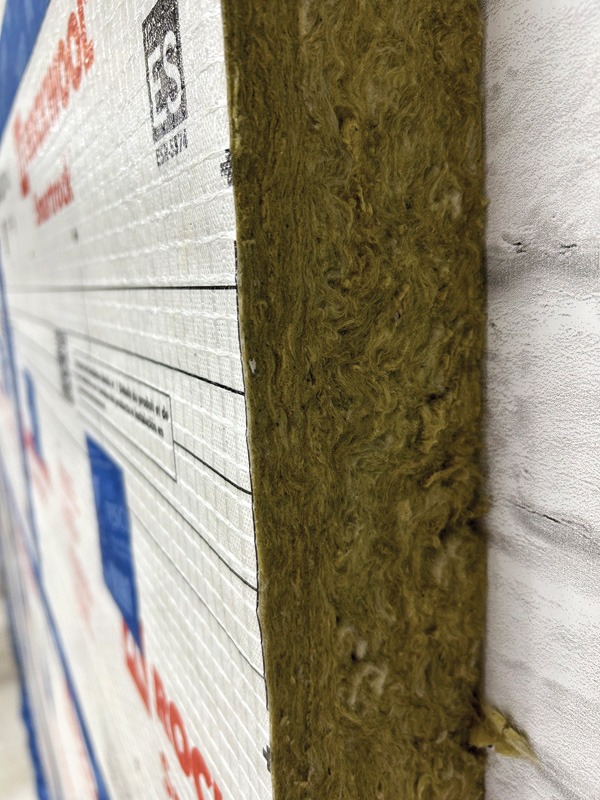

Stone wool is one insulation option that supports multiple goals during a retrofit. It is a high-performance building insulation material made from basalt rock. By melting stone at high temperatures and spinning it into cotton candy-like fibers, it becomes a durable, fire-resistant, and thermally efficient insulation product.

Specifiers and builders often choose stone wool insulation because it is inherently noncombustible. It will not develop toxic smoke or promote flame spread, even when exposed to a fire. Stone wool also offers excellent thermal performance, maintaining consistent indoor temperatures and improving energy efficiency. It is highly effective at absorbing sound to reduce noise transmission and is hydrophobic.

Proven stone wool solutions

Retrofits in New York City have become a proving ground for projects that prioritize energy efficiency, fire protection, and compliance with updated building codes. With neighborhoods dating back centuries and industrial and commercial properties now reaching 100 years or more, New York City property owners face growing demand for modern real estate amenities, while being forced to work with increasingly strict building codes and aging infrastructure.

Take a look at three different case studies where stone wool helps design teams meet their goals in retrofits.

Rainscreen overcladding system

New York City’s Upper East Side is home to a variety of multi-residential buildings, including a 160-unit residential co-op at East 97th Street.2 Built in 1961, the property is an early example of the white glazed brick buildings characteristic of development projects in the area during that period.

While the interior offers spacious units in a city known for its density, the appeal of these was offset by a failing facade. Inspections showed the exterior had no insulation or waterproofing membrane at all, and the back-up brick behind the glazed face-brick was also deteriorating. These inspections, required under Local Law 11, also presented significant non-compliance costs and inconvenience to co-op owners, who began looking for a long-term solution.

By 2018, a complete facade recladding was required. Rogers Partners Architects + Urban Designers took this as an opportunity to not only completely retrofit the building envelope to enhance performance, but reimagine and modernize the look of the exterior.

The overall goals of the retrofit were as follows:

- Remove the brick and upgrade the facade to improve long-term performance

- Help meet Plan NYC 2030 greenhouse gas reduction goals to reduce city-wide emissions by 30 percent

- Avoid compliance fines during subsequent facade inspections

- Increase property value

- Improve indoor environmental conditions

Replacing brick with brick would not meet these goals, as the original wall thickness offered no room for new insulation. Rogers Partners recommended an upgraded building envelope system using a high-performance rainscreen system. This solution would offer improved thermal performance, acoustic insulation, and better comfort and safety for the residents.

A porcelain tile cladding system was selected. Zoning regulations allowed for a 102-mm (4-in.) encroachment over the property line, which provided room to install a high-performance assembly behind the cladding. This assembly, including a semi-rigid black mat-faced stone wool insulation, was designed to meet Passive House standards. Co-op owners could enjoy improved thermal performance and comfort in their previously drafty building.

In addition to the performance advantages offered, the use of a black mat-faced stone wool insulation product meant that even with the new facade’s open-joint system, anywhere the matte black layer of the insulation may be visible, it does not detract from the aesthetic vision of the design. And stone wool’s inability to absorb moisture made it an ideal component of the rainscreen system.

EIFS

When working with buildings where the historic character of the exterior needs to be preserved, designers need to get creative. Building performance can be significantly enhanced by using EIFS on parts of the building that are not visible from the street side of the property. These integrated composite material systems offer an insulated, waterproof and non-combustible all-in-one solution.

Selecting an EIFS wall assembly that incorporates stone wool insulation provides an ASTM E84-compliant product, which meets the needs of specifiers and builders seeking fire-resistant-rated options. This was the case at Engine 16 (223 East 25th Street, N.Y.),3 a former firehouse located in Manhattan’s Kips Bay area. The firehouse had been relocated in the 1960s, and the building had deteriorated until Baxt Ingui Architects was brought on to revitalize the property in 2018.

The planned retrofit involved converting Engine 16 into a multi-use property, including two additional floors with residential units. All parties involved were committed to maintaining the historic facade on the front of the building. However, retrofitting the back and sides of the building with high-performance materials would increase energy efficiency and help the project comply with 2022 New York City building code.

Selecting an EIFS with stone wool insulation provided the building with passive fire resilience. The system also uses mechanical fasteners in addition to the typical adhesives used in EIFS products, which increases wind-load resistance, thereby helping to ensure the facade’s durability for upcoming decades.

In addition to meeting New York City building codes and fire protection requirements, when the retrofit was complete, Engine 16 was compliant with Passive House Institute’s (PHI) EnerPHit Classic certification. The use of EIFS, as well as air sealing and insulation done in the project was able to reduce the building’s heating and cooling needs by 80–90 percent.

Interior-insulated masonry and concrete

Masonry and concrete exterior buildings make up a significant part of the commercial, industrial, and institutional real estate portfolio in most North American cities. While these materials offer long-term durability, they also bring unique challenges when it comes to improving building performance.

Updating a masonry or concrete exterior, either through replacement or with overcladding, is not always feasible. Reasons could include historical or heritage preservation, where architectural details have to be maintained for aesthetic or durability considerations. These walls may also be load-bearing, which makes alterations or removals either very difficult or financially difficult. Building codes, including the International Existing Building Code or local zoning, may include restrictions on setbacks or proximity to adjacent buildings. These restrictions mean new cladding cannot be added over existing walls without exceeding the property line or encroaching on adjacent buildings.

Designers and specifiers in these circumstances may need to adopt interior insulation strategies as part of the retrofit, instead of relying on exterior systems.4 This approach means retrofit teams have to find ways to manage vapor and condensation, particularly during weather extremes in hot and cold weather.

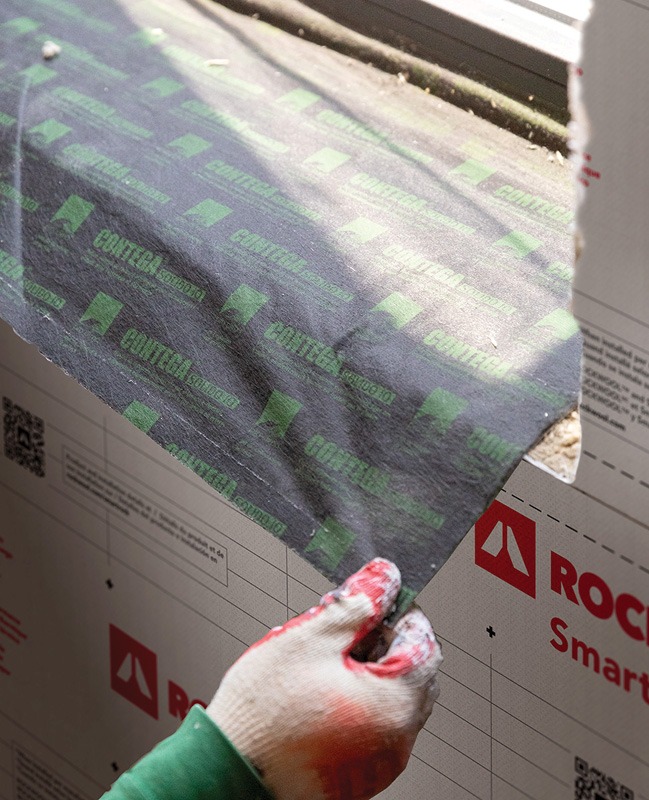

An innovative solution is available that helps address the unique challenges of this application. It begins with a vapor-permeable, fluid-applied air-water barrier, coupled with a stone wool continuous insulation (c.i.) board with an integrated smart vapor membrane. The stone wool product is also Class A-fire rated, meaning it can meet local fire resistance laws and ordinances, particularly in occupied spaces.

These products allow inward drying, while controlling outward condensation and air leakage, to avoid unseen condensation. The stone wool board is installed in tight contact with the existing masonry or concrete wall; and because the membrane is vapor variable, it offers optimal performance. Most simply explained:

- Low Class II vapor retarders in cold weather protect against condensation by slowing vapor diffusion to an acceptable level.

- Class III vapor semi-permeable retarders in warm weather allow drying to the interior—when humidity is high within the masonry or insulation layer, moisture can diffuse inward, allowing the materials to dry.

Stone wool insulation paired with a smart vapor member is a sustainable option for masonry and concrete buildings. It offers low Global Warming Potential (GWP) to reduce the carbon footprint of the retrofit project, and since it has no off-gassing, it can easily be installed in an occupied building, and removed with minimal disruption as part of future renovations.

One example where stone wool was used to increase building performance of an existing masonry building can be found at 369 Warren St. in Brooklyn.5 The building’s owner, 475 High Performance Building Supply, wanted to convert the former carriage house into a modern office space. The goals included achieving Passive House certifications, without significantly altering the building’s historic exterior.

The thermal performance of a 100-year-old carriage house differs significantly from the requirements of a modern shared office space, and the existing building lacks insulation behind the masonry. The project team selected a low-carbon insulation option that could be applied to all six sides of the building—floors, walls, and ceiling—to support its energy efficiency target.

Using a stone wool insulation with a smart vapor retarder also helped reduce the risk of condensation in the walls of the retrofitted facility. It also provided an exemplary acoustic performance and a high-quality indoor environment for new occupants. The completed project included a 0.3 on early blower door tests, indicating high airtightness.

Conclusion

Keeping existing buildings operating at their best through the future requires a holistic approach that considers how every system in the building interacts over time. Retrofits are inherently complex and need custom solutions each and every time.

Insulation is a critical element of these retrofits, working hand-in-hand with other building systems to ensure energy efficiency, occupant comfort, and envelope durability. Stone wool’s versatility—incorporated into rainscreen overcladding, EIFS, and interior-insulated masonry—makes it a proven solution to meet diverse retrofit challenges, including modern energy efficiency and fire resistance standards.

Retrofits bring aging buildings into the modern world, and the performance enhancements they offer are about more than upgrading degraded and damaged materials. By selecting the right solutions and materials, including products such as stone wool, these retrofits can meet today’s goals and targets while building something that lasts into the future.

Notes

3 Refer.

4 Learn more.

5 See.

Author

As a senior product manager at ROCKWOOL North America, Ryan Martin specializes in building insulation, overseeing product strategy for thermal and acoustic batts, exterior wall, and exterior insulation and finish system (EIFS) and stucco applications across residential and commercial construction. In his role, Martin regularly conducts field evaluations, translating business requirements into technical specifications to build market intelligence and strengthen proximity between ROCKWOOL and its customers. Martin also serves on the board of directors for the EIFS Council of Canada (EIFSCC) and is a member of the EIFS Industry Members Association (EIMA).

Key Takeaways

Retrofits are complex, system-wide undertakings that must balance energy efficiency, durability, safety, and occupant comfort. A holistic approach—integrating envelope, mechanical, fire protection, and interior systems—reduces risk and long-term costs. Stone wool insulation supports resilient retrofits by delivering non-combustibility, thermal and acoustic performance, moisture resistance, and compatibility with rainscreens, exterior insulation and finish system (EIFS), and interior continuous insulation (c.i.) strategies across varied climates and building types.