Benefits of specifying complete masonry veneer wall systems

Insulation

Depending on the design, one to three types of insulation may be needed in complete masonry veneer wall systems.

Framed wall insulation

If the structural backup wall is framed wood or steel, then insulation can be installed between the studs. It can be fiberglass, mineral wool blankets or batts, or sprayed polyurethane foam (SPF). Which to specify depends on the needed performance and the jobsite conditions. It is important to keep in mind all framing members—but steel studs in particular—act as thermal bridges between the inside and outside of the building, and will reduce the framing insulation’s effectiveness by up to 50 percent. This is one of the reasons why energy codes such as International Energy Conservation Code (IECC), American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 90.1, Energy Standard for Buildings Except Low-rise Residential Buildings, and ASHRAE 189.1, Standard for the Design of High-performance Green Buildings, prescribe continuous insulation over the studs as well as inside the cavity.

Continuous insulation

Continuous insulation can be semi-rigid (in the form of fibrous boards), rigid (in the form of plastic boards), or SPF. As water will get into the cavity, all continuous insulation should be highly water-resistant and not rely on facers to keep water out of the insulation.

It is important to note not all rigid continuous insulation is alike. In the Brick Industry Association’s (BIA’s) Technical Note 28B, “Brick Veneer/Steel Stud Walls,” it specifies a water-resistant, closed-cell, rigid foam insulation to keep water from penetrating into the sheathing. Although many types of insulation are said to be ‘closed-cell,’ when water absorption levels, molecular structure (i.e. hydrophobic versus hydroscopic), and cell structures are compared, there are differences. Extruded polystyrene is one good option for minimizing water penetration and absorption, because:

- the polystyrene molecule is hydrophobic, compared to the polyisocyanurate (polyiso) molecule, which is hydrophilic; and

- the XPS cell structure is truly small and ‘closed cell,’ compared to the larger and often-interconnected cells of polyiso.

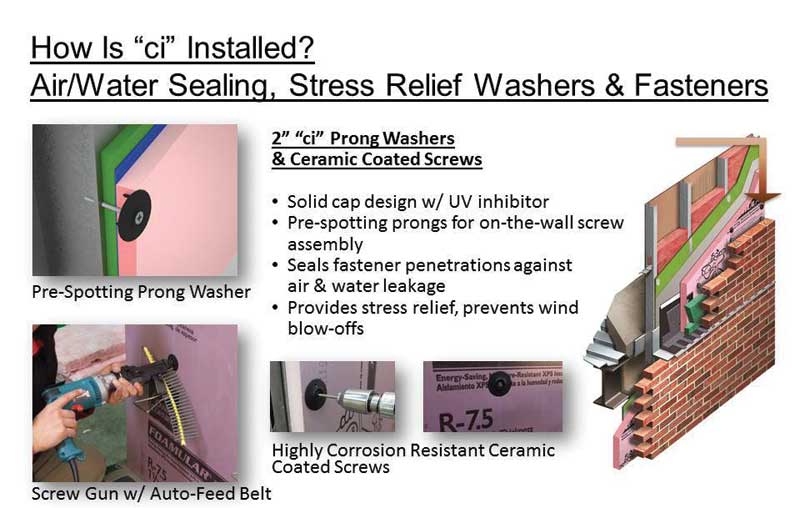

Specialized fasteners, including corrosion-resistant screws, are required to install rigid continuous insulation, plus specialized washers with enough surface area to pull the insulation tight against the substrate and create an air- and watertight seal around the screws. Since the wrong fasteners can pull out and the wrong washers can allow air and moisture infiltration, these components should be specified rather than left to the insulation contractor or mason.

SPF is also an effective insulator when properly applied, but because it is essentially manufactured in the field, it may have variable insulation quality, both between the studs and as continuous insulation. The installer must ensure the application temperature, nozzle pressure, rate of wand speed, and foam thickness are all correct to deliver the specified R-value. Since semi-rigid and rigid continuous insulations are factory manufactured, quality is consistent and reliable.

Fire safing insulation

Fire safing insulation is highly fire-resistant mineral wool insulation and is often required at the floor line on buildings designed with curtain wall systems, especially mid- and high-rise structures where smoke and fire must be prevented from spreading between floors. In situations where the floor assembly must be fire-resistance-rated, one route for the fire to spread is through and up the exterior curtain wall.

Fire safing insulation and smoke-sealed joints must be installed to limit fire spread up into and through the exterior curtain wall. Fire safing insulation is installed between the floor slab edge and the curtain wall insulation to contain the fire, and must be compression-fit to ensure a tight seal. As part of a firestopping system, this insulation does not have a fire rating on its own. Only complete firestopping systems have fire resistance ratings determined by ASTM E2307 and define the perimeter fire containment standard specifically designed to extend the rating of the floor assembly out to the exterior skin.