For the Birds: Considerations for effective specification of bird deterrence

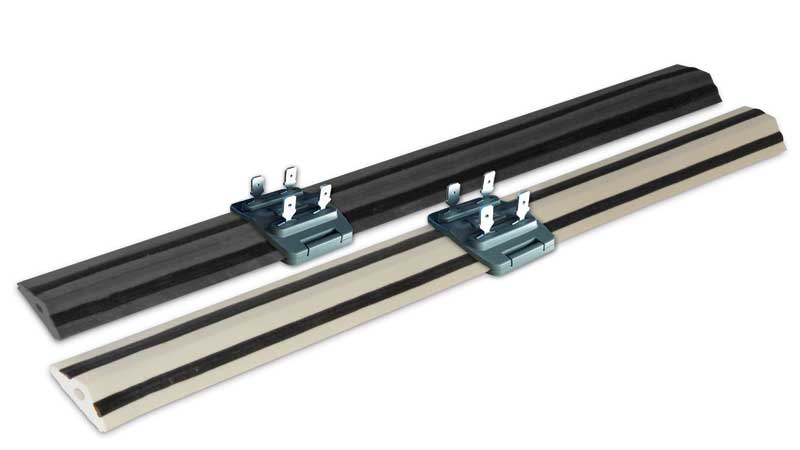

Photo courtesy Bird-X

Pricing considerations

It may be hard to believe the same system installed on one project can be twice or three times the cost on another project. The primary factor affecting pricing is accessibility of the work area. It is far easier to secure X number of linear feet of an adhesive-mounted system while walking along a roofline than on a façade ledge from an aerial work platform. Both the cost of the access equipment (booms or scaffolding) and with the speed at which work is done are key factors in determining cost. Complexity of installation adds to time as well.

Other factors for consideration are the working hours, required wage rates for the project, jobsite proximity to qualified labor pool, the level of component quality specified, the performance criteria of the system, installer qualification standards, and whether there is anything sole-sourced within the documents.

Accurate pricing for work in the planning stage is best handled by someone who has the product knowledge but also the installation construction management experience to help make informed budgetary decisions. Figure 2 provides an idea of pricing.

It’s just bird work, right?

There can often be problems with bird-control work done during the construction process—frustration with the products or available information, a lack of understanding by the contractor or subcontractor relative to performing in a construction environment, or simply poor results functionally or aesthetically from the work that gets done. Therefore, it is routinely underdeveloped in the construction documents or left out entirely from the project.

Most bird-control projects done in this country are on existing buildings rather than as part of new construction. In most cases, the building owner relies on pest control operators (PCOs) to solve an existing bird problem as they would a rodent or insect problem. Therefore, the manufacturers of bird deterrent systems have supported, catered to, and marketed to the pest control industry almost exclusively.

Typical installers from the pest industry (company or individual) are not adequately prepared for being involved in a construction process. They often want to glue down some spikes from the ladder on the pickup truck and get back to work checking mousetraps or applying chemical in a kitchen for roaches. Bird work done as part of the construction process is a very different animal—no pun intended. The project planning, project management, documentation, and procedural considerations of a construction project (either design/build or even just supply and install) are often beyond the capabilities of the traditional PCO.

There are numerous decisions that have to be made to properly plan for this work. For a specifier, the options are either to do the homework and make these decisions yourself, or throw it out there as design-build and rely on the person with the cheapest price to do the design of his cheapest build.

Going with design-build and a performance spec to lay off the liability on the contractor or using the manufacturers’ standard generic specifications gives away much of the decision-making power relative to the project—the results are rarely pretty. Considerations include:

- for netting: gauge, mesh size, color, hardware type, and mounting locations;

- for electric: conductive material, color, power source, water damming, adhesive type, and minimum voltage; and

- for spikes: base type, spike material, spike height, spike width, strip length, and anchorage.

Neither the manufacturer whose system is specified nor the selected subcontractor installer wants to be responsible and accept liability for the eventual and essential result: prevention or elimination of a bird problem. The manufacturer would tell you its product works where installed properly and can show there is nothing physically wrong with the components; the installer would say it installed what was requested in the desired location and required manner, but since it did not make the product, it cannot be responsible for the result.

At this point, there are two entities pointing fingers at each other. Unfortunately, the manufacturer’s warranty is limited to the quality of the product component manufacturing. (It will ship new components or material to replace those shown to have failed.) The manufacturers are not liable for the results of their components being assembled into a properly engineered system. What the customer (whether owner or architect) is left with is an expensive installation of components that do not do what they are supposed to. (For further thoughts on this, see “Getting Good Information About This Niche.”)