Improving the appearance of hot-dip galvanized steel

Altering the appearance of HDG steel

Although it can be difficult to control the initial appearance of hot-dip galvanizing, design professionals continue to turn to it for a modern industrial appearance or to complement the surrounding environment with a neutral gray. Though HDG coatings provide a unique aesthetic, there are ways to alter its appearance for projects where a desired sheen or color is an important attribute of the overall design.

Newly galvanized parts will dull slowly as they weather naturally in the environment, but a prematurely matte surface is achieved by applying a zinc-phosphate conversion coating. This procedure is typically used for rural environments or wilderness areas where surface reflectivity must be reduced prior to installation for safety or environmental concerns. Some galvanizing plants can dull the coating using an immersion process, but a spray or immersion application may also be performed by a third party.

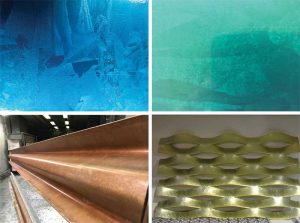

To alter coloration of the galvanized coating while preserving other interesting visual aspects of the metallic coating, metal surface treatments can provide a distinctive alternative. These post-galvanizing treatments do not affect the corrosion protection and are applied either by immersion in solution or spray application.

Photo courtesy TecCoat Metal Treatments

For example, a natural earth tone can be achieved to blend galvanized components within a natural landscape by applying a color treatment that reacts with the zinc surface to develop a mottled and rustic, brown finish often associated with a historical aesthetic. The final effect is often compared to weathering steel. Where a more vibrant color is preferred, other passivation technologies, such as polymer-based, water- borne products specifically designed for use over zinc surfaces, can be spray applied. They dry within seconds to offer long-lasting translucent colors in a variety of hues (Figure 5). Due to the variety of initial appearances possible, it is impossible to guarantee spangles or other features will be visible underneath a translucent surface treatment.

Case study: Black Mountain Express ski lift

Ski lifts are built to provide safe mountain transportation for winter enthusiasts while also withstanding cold, wet winter conditions, and the abrasive dings and dents often incurred to recreation equipment. However, in some cases, such as when the ski lift operates in a United States Department of Agriculture (USDA) National Forest, minimizing the impact on the environment must also be considered. The USDA Forest Service has strict reflectivity requirements to limit the environmental impact of such structures. Since zinc is a naturally occurring element and is 100 percent recyclable, the HDG coating inherently limits environmental impact. However, its initial appearance can be bright and shiny, providing an unwanted contrast to the surrounding natural environment. To combat this issue, HDG coating on ski lifts at the Black Mountain Express Ski Lift, Colorado, was intentionally dulled using a zinc-phosphate conversion coating. This allowed the specifier to meet reflectivity requirements without sacrificing the maintenance-free corrosion protection provided by galvanized steel. Instead, the owner can enjoy decades of maintenance-free life while reaping the various benefits HDG steel provides in this application.

Project Neon Sign Structures with Nevada Department of Transportation

The recently completed Project NEON in Las Vegas, Nevada, was one of the largest public works projects in the state’s history. The Nevada Department of Transportation (NDOT) widened 6 km (3.7 mi) of the busiest stretch of Interstate 15 between Sahara Avenue and the “Spaghetti Bowl” interchange in downtown Las Vegas. This section of highway sees 300,000 vehicles daily, and over 25,000 lane changes an hour with traffic expected to double by 2035. Given the visibility and the size of this project, NDOT wanted the galvanized structures (e.g. overhead signs, cable railing, chain-link fence, monopoles, sign posts, guardrails, and end terminals) to have a more natural and rustic brown appearance. This was an ideal design choice for this iconic stretch of Interstate in downtown Las Vegas with its picturesque mountains and desert landscape. To achieve this aesthetic, the project team applied a proprietary galvanized steel surface treatment to give the structures an earthy brown finish. The solution is also low maintenance, which is ideal since this is the busiest highway in Nevada and NDOT wanted to mitigate traffic delays that would be necessary for touch-ups. Last but not least, because this treatment goes on top of galvanized surfaces, NDOT did not have to sacrifice the superior corrosion resistance afforded by hot-dip galvanized steel.

Painting or powder-coating over galvanizing

Where a certain color other than a natural, gray metallic is preferred, the HDG coating may be painted or powder-coated, known as a duplex system. In addition to a specified hue and texture, duplex systems provide improved longevity, 1.5 to 2.3 times the combined lifetimes of both systems, as the result of a synergistic effect between the coatings (Consult Duplex systems: Hot-Dip Galvanizing Plus Painting by J.F. Eijnsbergen, published in (1994)). Amsterdam: Elsevier. The paint or powder-coating should be specified based on the intended use of the part, application method, environmental concerns, and the desired appearance. For assistance in evaluating the available options designed to work well over hot-dip galvanized surfaces, it is best to consult a paint manufacturer directly or reference the Society for Protective Coating (SSPC) Guide 19, Selection of Protective Coatings For Use Over Galvanized Substrates. SSPC Guide 19 is a valuable resource to guide specifiers in selecting an appropriate liquid coating system for the duplex system.

Surface preparation is the most important step in ensuring the appearance and overall performance of painted or powder-coated HDG steel meets the desired expectations. The following standards clarify the steps necessary to prepare the galvanized surface for a wide range of liquid coating systems:

- ASTM D6386, Practice for Preparation of Zinc (Hot-dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces for Painting; and

- ASTM D7803, Practice for Preparation of Zinc (Hot-dip Galvanized) Coated Iron and Steel Product and Hardware Surfaces for Powder Coating.

After coating selection and preparation of the hot-dip galvanized surface, the paint or powder-coating should always be mixed, applied, and cured in accordance with the manufacturer’s instructions.