What is happening behind stucco and manufactured stone?

Further, gypsum sheathing is vapor permeable and OSB sheathing is vapor impermeable.

How is high vapor permeability a problem? When a reservoir cladding discharges inwardly, the inwardly driven vapor can easily pass through the exterior gypsum sheathing and damage the wall cavity and interior finishes.

How is lower vapor permeability a problem? The wall assembly itself cannot dry outward, but, there is an additional issue with OSB. Unlike plywood, when OSB is wetted from the exterior, it is incapable of redistributing moisture within itself. OSB is significantly lower in permeance than plywood. Plywood can pull water into its structure and wick it away from the point of wetting and subsequently release it both inward and outward as it increases in permeance. OSB has none of those properties. With OSB, the moisture redistribution must happen on its surface. Hence, the absolute need for an airspace over its exterior surface.

On top of this, Lstiburek explains the physical characteristics of stucco used in applications have also changed. Over the years, the components have gone from lime-based, lime-Portland cement-based, Portland cement-based, and polymer modified. With each step it has gotten stronger, but also created a less vapor permeable mixture. Today’s stuccos do not breathe as well as the old kinds. These changes have led to very significant problems with stucco, particularly in places where it rains a great deal.

Building professionals understand it is critical to keep water and dampness from getting into a structure by preventing moisture from moving through the wall from the outside. This is accompanied by putting the right measures in place to keep any moisture from penetrating the system.

The initial solution was to use two layers of WRB—the outer layer would act as a bond break and the inner one would be the ‘true’ dimensionally stable WRB. However, these assemblies had lacked enhanced drainage and drying.

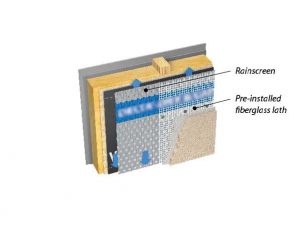

Professionals have since learned the more effective means of accomplishing both is to provide a drainage mat between the bond break and the WRB. Moisture can be fully blocked by uncoupling the stucco from the rest of the wall and installing the stucco over a vented and drained air gap.

Best practices when installing commercial stucco wall assemblies

In a steel stud wall with gypsum sheathing it is very important to install some type of water and air control layer on the exterior of the gypsum sheathing. This layer also needs to be vapor open to allow the wall to dry outward. This layer could be a fluid-applied, fully adhered, vapor-permeable membrane. On it could be sheet product such as a WRB film. Another option would be gypsum sheathing with an integral water control layer with joint treatment. Over this layer goes a drainage mat that resists hydrostatic pressure and prevents inward vapor drive, such as a dimple mat with a mortar screen that allows for air gaps on both the interior and exterior side of the membrane. The stucco layer goes over the mat.

Nothing changes for a steel stud wall with OSB sheathing except when the OSB sheathing may have a fluid-applied or an integral water control layer.

With a drained and ventilated stucco cladding, the wall assembly can dry to the outside into the air gap behind the stucco. With a vapor-closed drainage mat, inward vapor drives through the stucco are completely blocked.

The same approach works behind natural stone claddings and manufactured stone veneers.

Providing a gap between the stucco and the substrates creates an airspace between the cladding and the rest of the wall. This gap provides two important functions—one is to allow outward drying through a vapor-open, water- and air-control layer, and the second is to prevent inward wetting as a result of moisture coming through a reservoir cladding. With the right kind of space, stucco will last hundreds of years.